Axiom Precision Manufacturing was engaged to work on the Silvershield counter-improvised Explosive Device project in partnership with the Defence Science and Technology Group (DSTG).

DSTG is a national organisation bringing together science, technology and innovation to deliver scientific advice and solutions that provide capability enhancement for Australian defence.

THE PROJECT

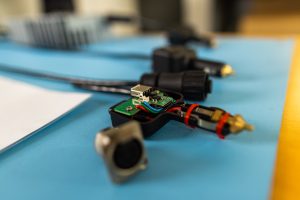

Developed under DSTG’s Redwing program, Axiom provided mechanical and electro-mechanical design input, along with the manufacture and assembly of Silvershield units; an evolution of the soldier mounted protection unit.

During the project, DSTG required additional verification for cable inductance and voltage drop across testing nodes for Silvershield. These cable testing requirements addressed DSTG’s need to rapidly provide further verification on automated testing jigs.

OUTCOMES

The Axiom team adapted to the sudden shift in requirements, improving the systems for testing and validation promptly, ensuring the pre-determined schedule was adhered to.

System testing was altered to meet the standards specified, ensuring tolerancing was met, and pursued procedural standard review to an AS9100 level.

This project led to the acquisition of additional electrical equipment, increasing our internal testing capabilities, as well as the amendment to subcontracted calibration procedures for the automated test jig.

For an individual component or complete electro-mechanical solution, our experienced team can help design and deliver your project to exacting specifications.